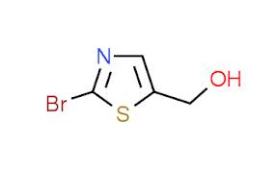

Since the discovery of 5-Hydroxymethylthiazole can be used for synthesis of second-generation anti-AIDS drugs ritonavir (Ritonavir), scientists have done many studies on the synthesis method of 5-Hydroxymethylthiazole.

Since the discovery of 5-Hydroxymethylthiazole can be used for synthesis of second-generation anti-AIDS drugs ritonavir (Ritonavir), scientists have done many studies on the synthesis method of 5-Hydroxymethylthiazole.

Typically, 5-Hydroxymethylthiazole synthesized mainly in two ways. The first one is 2 - chloro -5 - (chloromethyl) thiazole as the raw material by esterification, hydrolysis and catalytic hydrogenation dechlorination, after 3 steps Synthesis of 5-Hydroxymethylthiazole. The process requires the use of the esterification phase transfer catalyst, the reaction time is long, after-treatment troublesome, byproduct during the reaction are more, the need for active carbon, high cost.

The second is: 1-chloro-5 - (chloromethyl) thiazole dechlorination after hydrolysis and catalytic hydrogenation to give 5-Hydroxymethylthiazole(CAS NO: 38585-74-9) process, the process more hydrolysis byproducts, to active carbon, high cost; while catalytic hydrogenation dechlorination equipment investment, hydrogen explosive, requiring a higher security measures.

In this Article, I will introduce a new approach: 1 - chloro-5 - chloromethylthiazole as raw material through esterification, reduction and hydrolysis Synthesis of 5-Hydroxymethylthiazole process. Actually, we have done little change on this method, so that this method is more efficient.

Main raw materials and reagents

Materials: 2-chloro-5-chloromethyl thiazole, industrial grade; Zinc; Ethanol (95% mass fraction), ethyl acetate, acetic acid, acetate trihydrate Sodium, anhydrous sodium sulfate were of analytical grade.

Reagents: Perkin Elmer Clarus 500 Gas Chromatograph, Agi-lent LC-MSD1100 type liquid a mass spectrometer, VarianUnity INOUA-300-type superconducting NMR spectrometer, Thermo Fisher AVATAR 330 FT-IR. Perkin Eliner 2400-1I elemental analyzer.

Reagents: Perkin Elmer Clarus 500 Gas Chromatograph, Agi-lent LC-MSD1100 type liquid a mass spectrometer, VarianUnity INOUA-300-type superconducting NMR spectrometer, Thermo Fisher AVATAR 330 FT-IR. Perkin Eliner 2400-1I elemental analyzer.

Synthesis conditions:

Suitable esterification conditions: 2-chloro-5-chloromethyl-thiazole amount of 1mol, ethanol (boron = 80% to 90%) as a medium, material ratio: n (2-chloro-5-chloromethyl thiazole) : n (sodium acetate) = 1:2, refluxing for 5 ~ 6 h.

Reductive dechlorination process conditions: n (2 - chloro-5-chloromethyl thiazole): n (zinc) = 1:3, refluxing for 1 h.

Hydrolysis conditions: the base w (NaOH) in a 25% hydrolyzed, the reaction temperature is 70 ~ 75 ℃, reaction 2h. 5 - (hydroxymethyl) thiazole yield of 76.23%, w (5 a hydroxymethyl thiazole) ≥ 99% (GC, peak area normalization method). By 20I. After the reactor was scaled, 5-hydroxymethylthiazol yield increased to 81. 00%.

Process was improved, the esterification reaction does not require a phase transfer catalyst and ethyl acetate, solvent recovery and less consumption, the product simple treatment can be carried out after the next reaction; zinc / acetic acid reductive dechlorination method of operation simple, no catalyst is added, and the reaction time is short, easy to control; process improvement, the 5-Hydroxymethylthiazole increased yield from 54% to 76.23%.

没有评论:

发表评论